Before starting our article, do not forget to review the following services of Durfoam:

Polyethylene foam is a versatile and cost-effective material that has become the ultimate solution for cushioning in various industries. With its lightweight nature, exceptional durability, and superior shock absorption properties, polyethylene foam provides optimal protection for delicate and fragile items during transportation or storage. But its benefits don’t stop there. Polyethylene foam also offers thermal insulation, making it suitable for packaging solutions for temperature-sensitive products.

One of the key advantages of polyethylene foam is its resistance to water and moisture. This means that even in humid or wet conditions, the cushioning material remains effective, ensuring the safety of the packaged items. Additionally, polyethylene foam can be easily customized to fit specific product dimensions and shapes, making it a versatile solution for cushioning needs in various industries.

Not only is polyethylene foam a reliable and efficient cushioning material, but it is also environmentally friendly. It can be recycled and reused, reducing waste and promoting sustainability. This makes it an attractive choice for companies looking to minimize their environmental impact.

Another significant advantage of polyethylene foam is its cost-effectiveness. Compared to other cushioning materials, polyethylene foam offers a cost-effective solution without compromising on performance. Its longevity and reusability further contribute to its value for money, making it a long-lasting investment for businesses.

Furthermore, the lightweight nature of polyethylene foam helps reduce shipping costs. As it adds minimal weight to the overall package while providing optimal cushioning, businesses can save on transportation expenses.

In conclusion, polyethylene foam is the ultimate solution for cushioning due to its lightweight and durable nature, shock absorption and impact resistance properties, thermal insulation capabilities, water and moisture resistance, customizability, eco-friendliness, cost-effectiveness, longevity, reusability, and reduced shipping costs. Its applications in various industries make it a highly sought-after material for cushioning needs.

Lightweight and Durable

Polyethylene foam is a highly sought-after material for cushioning applications due to its unique combination of lightweight properties and exceptional durability. This makes it the ultimate solution for protecting delicate and fragile items during transportation or storage.

One of the key advantages of polyethylene foam is its lightweight nature. Unlike other cushioning materials that can add significant weight to packages, polyethylene foam adds minimal weight while still providing optimal cushioning. This not only helps reduce shipping costs but also ensures that the overall package remains lightweight and easy to handle.

Despite its lightweight nature, polyethylene foam is incredibly durable. It can withstand heavy impacts and compression without losing its cushioning properties, making it ideal for protecting items from shocks and impacts during transit. Whether it’s fragile electronics, glassware, or sensitive equipment, polyethylene foam provides reliable cushioning to prevent damage.

Furthermore, polyethylene foam is resistant to water and moisture, ensuring that the cushioning material remains effective even in humid or wet conditions. This makes it suitable for a wide range of applications, including packaging solutions for temperature-sensitive products.

In addition to its cushioning capabilities, polyethylene foam is also highly customizable. It can be easily cut and shaped to fit specific product dimensions and contours, making it a versatile solution for cushioning needs in various industries. Whether it’s a small electronic device or a large piece of machinery, polyethylene foam can be tailored to provide the perfect fit and protection.

Lastly, polyethylene foam is an environmentally friendly option. It can be recycled and reused, reducing waste and promoting sustainability. This makes it a cost-effective choice for businesses looking to minimize their environmental impact while still ensuring top-notch cushioning for their products.

In summary, polyethylene foam’s lightweight nature, exceptional durability, water resistance, customizability, and eco-friendly properties make it the ultimate solution for cushioning applications. Whether you’re shipping delicate items or packaging temperature-sensitive products, polyethylene foam provides the perfect balance of protection, versatility, and cost-effectiveness.

Shock Absorption and Impact Resistance

When it comes to cushioning materials, polyethylene foam stands out for its exceptional shock absorption and impact resistance properties. This makes it the ultimate solution for protecting delicate and fragile items during transportation or storage.

Polyethylene foam has the ability to absorb and disperse impact energy, effectively cushioning the item and minimizing the risk of damage. Its unique cellular structure allows it to compress under pressure and then quickly regain its original shape, providing reliable protection against shocks and impacts.

Whether it’s fragile glassware, sensitive electronics, or valuable artwork, polyethylene foam ensures that your items remain safe and intact. Its superior shock absorption capabilities make it an ideal choice for industries such as electronics, automotive, aerospace, and shipping.

In addition to shock absorption, polyethylene foam also offers excellent impact resistance. This means that even if the cushioning material is subjected to heavy impacts or pressure, it will not break or lose its protective properties. This durability ensures that your items are well-protected throughout their journey.

With polyethylene foam as your cushioning material, you can have peace of mind knowing that your delicate and fragile items are in safe hands. Its shock absorption and impact resistance properties make it the go-to choice for ensuring the protection and preservation of your valuable goods.

Thermal Insulation

Thermal insulation is a crucial factor to consider when it comes to packaging solutions for temperature-sensitive products. Polyethylene foam not only provides excellent cushioning but also offers exceptional thermal insulation properties. This makes it an ideal choice for protecting items that are sensitive to temperature changes during transportation or storage.

With its ability to resist heat transfer, polyethylene foam acts as a barrier, preventing temperature fluctuations from affecting the packaged products. Whether it’s keeping perishable goods cool or maintaining the warmth of sensitive medical supplies, polyethylene foam ensures that the desired temperature is maintained throughout the shipping process.

Furthermore, polyethylene foam’s thermal insulation properties are enhanced by its closed-cell structure. This structure traps air within the foam, creating a layer of insulation that minimizes heat transfer. As a result, products can be safely transported without the risk of temperature-related damage.

Additionally, polyethylene foam’s thermal insulation capabilities can be further optimized by incorporating it into customized packaging designs. By creating a snug fit around the products, the foam maximizes its insulating properties and provides an added layer of protection against temperature fluctuations.

In summary, polyethylene foam’s ability to offer both cushioning and thermal insulation makes it an excellent choice for packaging solutions for temperature-sensitive products. Its lightweight nature, durability, and customizable characteristics further contribute to its suitability for various industries. Whether it’s protecting delicate electronics or preserving the freshness of food items, polyethylene foam provides a reliable and efficient solution.

Water and Moisture Resistance

Water and moisture can pose a significant threat to cushioning materials, compromising their effectiveness and durability. However, polyethylene foam stands out in this aspect, offering exceptional water and moisture resistance. This unique characteristic ensures that the cushioning material remains effective even in humid or wet conditions.

When it comes to protecting delicate and fragile items during transportation or storage, the ability of polyethylene foam to resist water and moisture is of utmost importance. Whether it is rain, spills, or high humidity, polyethylene foam acts as a barrier, preventing water from seeping into the cushioning material and compromising its structural integrity.

This water and moisture resistance feature makes polyethylene foam an ideal choice for a wide range of applications. It can be used in packaging solutions for products that are susceptible to damage from moisture, such as electronics, pharmaceuticals, and food items. By providing a protective cushioning layer that remains unaffected by water, polyethylene foam ensures that these products reach their destination in optimal condition.

Furthermore, the water and moisture resistance of polyethylene foam also contributes to its longevity and reusability. Even after exposure to wet or humid conditions, the foam retains its cushioning properties and can be used repeatedly. This not only reduces the need for frequent replacements but also adds to the cost-effectiveness of polyethylene foam as a cushioning solution.

In summary, the water and moisture resistance of polyethylene foam makes it a reliable and effective choice for cushioning applications. Its ability to withstand wet or humid conditions ensures that the cushioning material remains intact, providing optimal protection for delicate items. Whether it is for packaging solutions or other cushioning needs, polyethylene foam offers peace of mind in environments where water and moisture are a concern.

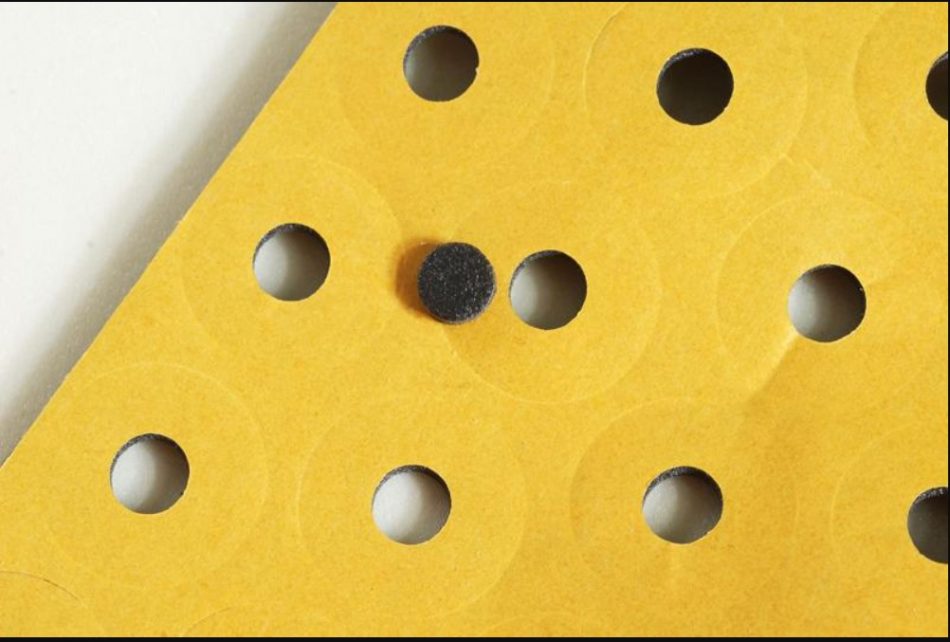

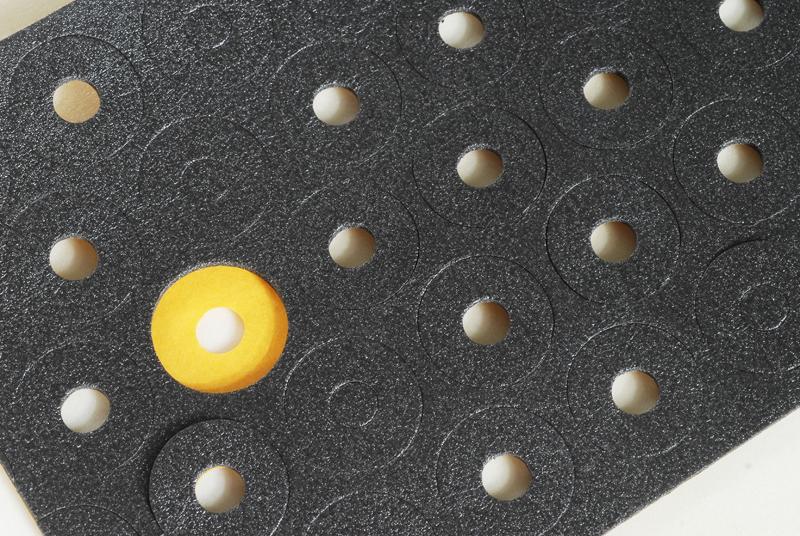

Customizable and Versatile

Polyethylene foam is a highly customizable and versatile material that can be easily tailored to fit specific product dimensions and shapes. This makes it an ideal solution for cushioning needs in various industries. Whether you need to protect delicate electronics, fragile glassware, or heavy machinery, polyethylene foam can be molded, cut, and shaped to provide a perfect fit and maximum protection.

One of the key advantages of polyethylene foam is its ability to conform to the contours of the product, ensuring a snug and secure fit. This is particularly important when dealing with irregularly shaped items that require customized cushioning. By using polyethylene foam, you can ensure that your products are well-protected during transportation, storage, and handling.

In addition to its customizability, polyethylene foam offers versatility in terms of its applications. It can be used in a wide range of industries, including electronics, automotive, aerospace, medical, and more. Whether you need cushioning for sensitive electronic components, automotive parts, or medical devices, polyethylene foam can be adapted to meet your specific requirements.

Furthermore, polyethylene foam is available in various densities, thicknesses, and colors, allowing you to choose the right material for your needs. Whether you require a soft and flexible foam for delicate items or a denser foam for heavier objects, polyethylene foam can be customized to provide the desired level of cushioning and protection.

In summary, polyethylene foam’s customizability and versatility make it an excellent choice for cushioning needs in various industries. Its ability to be easily molded, cut, and shaped ensures a perfect fit for specific product dimensions and shapes. Whether you need to protect fragile items or heavy machinery, polyethylene foam can be tailored to provide optimal cushioning and protection.

Eco-Friendly and Recyclable

Polyethylene foam is a highly eco-friendly and recyclable material, making it a sustainable choice for cushioning needs. By being able to be recycled and reused, polyethylene foam helps reduce waste and minimize the environmental impact. This makes it an excellent option for companies and industries that prioritize sustainability and want to contribute to a greener future.

One of the key advantages of polyethylene foam is its recyclability. When the foam reaches the end of its life cycle, it can be recycled and transformed into new foam products or other useful materials. This not only reduces the amount of waste that ends up in landfills but also conserves valuable resources by giving the foam a second life.

In addition to its recyclability, polyethylene foam also promotes sustainability through its reusability. Due to its exceptional durability, the foam can be reused multiple times before it needs to be recycled. This extends its lifespan and reduces the need for constant replacement, making it a cost-effective and environmentally friendly choice.

Furthermore, the production process of polyethylene foam itself is relatively energy-efficient and has a lower carbon footprint compared to other cushioning materials. This further contributes to its eco-friendly nature and makes it a responsible choice for businesses looking to reduce their environmental impact.

In summary, polyethylene foam is not only an effective cushioning material but also an environmentally friendly and recyclable option. By choosing polyethylene foam for cushioning needs, companies can reduce waste, promote sustainability, and contribute to a greener future.

Cost-Effective Solution

Polyethylene foam is a cost-effective cushioning solution that stands out among other materials. Its affordability combined with its high performance makes it a valuable choice for various industries. Whether you need cushioning for delicate electronics, fragile glassware, or heavy machinery, polyethylene foam delivers exceptional protection without breaking the bank.

Compared to alternative cushioning materials such as bubble wrap or Styrofoam, polyethylene foam offers superior value for money. Its durability ensures that it can withstand repeated use, reducing the need for frequent replacements. This longevity translates into long-term cost savings for businesses.

Furthermore, polyethylene foam’s lightweight nature helps reduce shipping costs. As it adds minimal weight to the overall package, businesses can save on transportation expenses while still providing optimal cushioning for their products. This not only benefits the bottom line but also contributes to a more sustainable and eco-friendly approach to packaging.

Additionally, polyethylene foam’s versatility adds to its cost-effectiveness. It can be easily customized to fit specific product dimensions and shapes, eliminating wastage and maximizing efficiency. This flexibility allows businesses to optimize their cushioning solutions according to their unique requirements, further enhancing the overall value of polyethylene foam.

In conclusion, polyethylene foam offers a cost-effective cushioning solution that delivers exceptional performance. Its affordability, durability, and versatility make it the ultimate choice for businesses seeking effective and efficient cushioning without compromising on quality.

Longevity and Reusability

When it comes to cushioning materials, durability and longevity are key factors to consider. Polyethylene foam stands out as an excellent choice in this regard. Thanks to its exceptional durability, polyethylene foam can be used repeatedly, making it a long-lasting and cost-effective solution for cushioning needs.

One of the main advantages of polyethylene foam is its ability to withstand repeated use without losing its cushioning properties. This means that even after multiple impacts, the foam will continue to provide reliable protection for your valuable items. Whether you are shipping fragile electronics or delicate glassware, polyethylene foam ensures that your products remain safe and secure.

Furthermore, the reusability of polyethylene foam contributes to its cost-effectiveness. Instead of constantly replacing cushioning materials, you can rely on polyethylene foam to provide long-term protection. This not only saves you money but also reduces waste, making it an environmentally-friendly choice.

Additionally, polyethylene foam’s durability and reusability make it a versatile option for various cushioning needs. Its ability to withstand multiple uses makes it suitable for applications in industries such as electronics, automotive, and furniture. Whether you need to protect delicate components during transportation or provide comfortable seating, polyethylene foam delivers reliable performance.

In conclusion, the longevity and reusability of polyethylene foam make it an exceptional choice for cushioning needs. Its durability ensures that your products remain protected even after repeated impacts, while its reusability offers a cost-effective and sustainable solution. With polyethylene foam, you can have peace of mind knowing that your items are cushioned by a material that is built to last.

Reduced Shipping Costs

The lightweight nature of polyethylene foam is a key factor in reducing shipping costs. Unlike heavier cushioning materials, polyethylene foam adds minimal weight to the overall package without compromising on its ability to provide optimal cushioning. This lightweight feature not only makes the package easier to handle during transportation but also helps to minimize shipping expenses.

When shipping products, the weight of the package plays a significant role in determining the shipping costs. Heavier packaging materials can increase the overall weight of the package, resulting in higher shipping fees. However, with polyethylene foam, the lightweight nature of the material ensures that the package remains as light as possible, reducing the shipping costs.

Furthermore, the reduced weight of the package also has a positive impact on the overall logistics and supply chain. Lighter packages are easier to handle, stack, and load onto transportation vehicles, saving time and effort during the shipping process. This efficiency not only decreases the risk of accidents or damages but also improves the overall productivity and effectiveness of the shipping operations.

In summary, the lightweight nature of polyethylene foam is a significant advantage when it comes to reducing shipping costs. By adding minimal weight to the package while providing optimal cushioning, polyethylene foam helps businesses save on shipping expenses and improve their logistics operations. With its ability to offer cost-effective cushioning solutions, polyethylene foam proves to be a reliable choice for various industries looking to optimize their shipping processes.