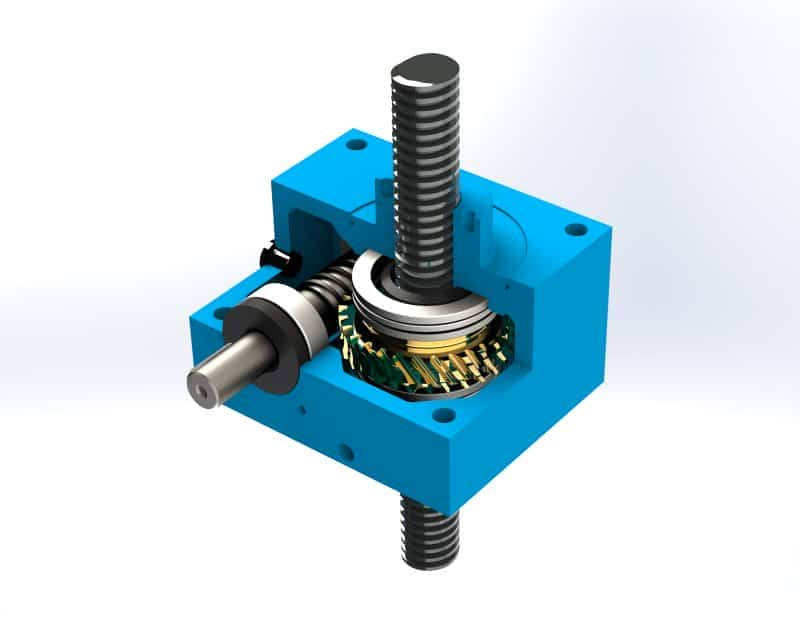

Screw jacks are powerful and versatile linear actuators that translate rotary motion into vertical lifting or pushing. They come in various configurations to suit a wide range of applications. But with so many options, selecting the ideal screw jack for your specific needs can seem daunting. This article will guide you through the key factors to consider to ensure you make the best choice.

Understanding Your Requirements

The first step is to clearly define your application’s requirements. Here are some crucial aspects to consider:

- Load Capacity: This refers to the maximum weight the screw jack can safely lift or push. It’s vital to choose a jack with a capacity exceeding your anticipated load to prevent damage or failure.

- Duty Cycle: This signifies the percentage of time the screw jack will be operational in a given period. For instance, a jack operating continuously throughout the day would have a 100% duty cycle. Selecting a screw jack suited for your application’s duty cycle ensures it can handle the workload without overheating or premature wear.

- Speed and Precision: Ball screw jacks excel in high-speed and high-precision applications due to their low friction and smooth operation. Machine screw jacks, while slower, are sufficient for moderate-speed tasks and provide self-locking at rest, eliminating the need for an additional brake.

- Environmental Conditions: If the screw jack will operate in extreme temperatures, dusty environments, or around moisture, consider material selection and protective measures to ensure proper function and longevity.

- Space Constraints: Screw jacks come in various sizes and configurations. If space is limited, consider a low-profile jack or a design that integrates well within your application’s footprint.

For more information on screw jack design and material selection, you can visit MechJacks https://mechjacks.com/en/. MechJacks is a leading manufacturer of high-quality screw jacks, offering a wide range of options to suit various industrial applications.

Two Main Types of Screw Jacks

Once you understand your requirements, you can delve into the two primary types of screw jacks:

- Machine Screw Jacks: These jacks utilize a threaded screw meshing with a helical groove in the lifting nut. They are known for their affordability, simplicity, self-locking ability, and suitability for static loads or lower duty cycle applications.

- Ball Screw Jacks: These jacks incorporate balls between the screw and nut, reducing friction and enabling smoother, more precise, and higher-speed operation. They are ideal for applications requiring high precision, frequent movement, and longer duty cycles.

Additional Considerations

Beyond the core factors, consider these additional aspects when finalizing your selection:

- Customization: Many manufacturers offer customization options such as end-of-travel limit switches, integrated brakes, and corrosion-resistant materials.

- Cost-Effectiveness: While initial price is important, factor in long-term costs like maintenance and potential future upgrades.

- Manufacturer Reputation: Choose a reputable manufacturer with a history of producing high-quality and reliable screw jacks.

By carefully considering these factors and consulting with a screw jack specialist if needed, you can ensure you select the screw jack that perfectly matches your application’s requirements.